①Technical Overview | Product Specifications

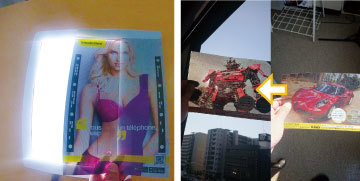

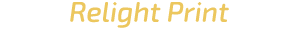

This is a printing technology that uses the optical illusion of creating a difference between light and dark by irradiating strong light from the back, making dark areas unrecognizable to the human eye.

In backlighting, objects appear to be darker.When the light is "forward", the object appears to be brighter.

RELIGHT PRINT is a patented product that can switch between two different types of data, printed using the backlighting principle described above and the "stacking-less calculation data processing method" developed by SO-KEN.

About an arithmetic data processing method that does not require addition.

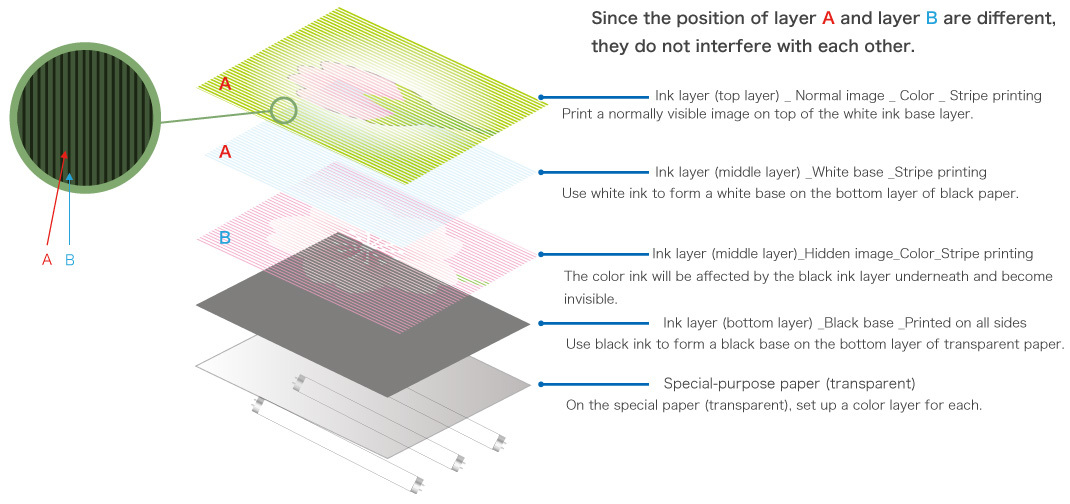

Special arrangement that is completed by inkjet.

How printing works (RELIGHT PRINT)

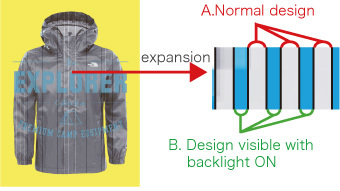

This is a printing technology that allows you to see two different designs on a single medium: a normal design in non-transparent ink printed on a transparent sheet, and a design in translucent ink that emits light when illuminated by a backlight.

Under normal conditions, we can see the design of A. However, when the design of B is illuminated by the strong light from the back, the difference between light and dark makes A look black and invisible to the human eye. When the light from the back is turned off and the brightness becomes moderate, the A design can be recognized again.

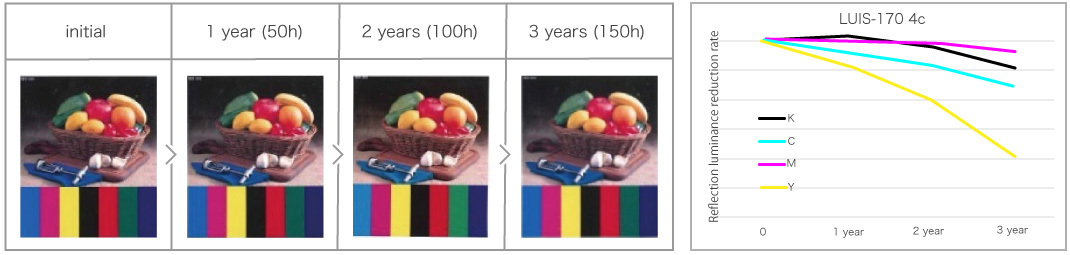

Ink specifications and weather resistance

MIMAKI - Genuine UV curable ink CMYKW

Weather resistance

| Weather resistance test conditions | ISO11341 1 | Irradiance | 60w/ ㎡ Permanent irradiation |

| Black panel temperature | 65 | Test chamber temperature | 38 |

| Relative humidity | 70% Equivalent to 1 year = 500 hours (reference value) |

Shower every 2 hours for 18 minutes | |

②Notes on installation and use

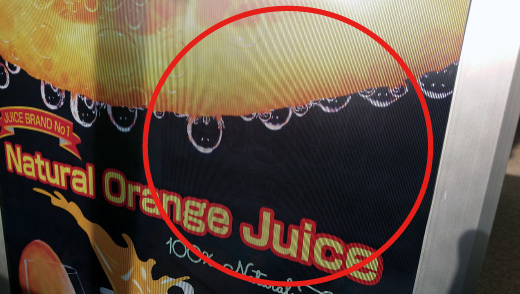

Precautions in sunlight and excessively bright environments

Please note that the design will not change when the backlight is turned on under sunlight, but the design will change when the backlight is turned on after sunset.

Notes on RELIGHT PRINT design

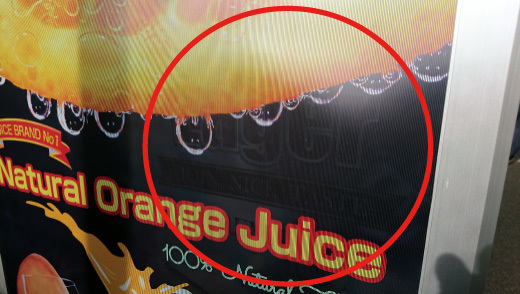

What is a Spoiler?

The standard type, RELIGHT PRINT paper, has a versatile gray density, but depending on the design to be combined, this phenomenon may occur.

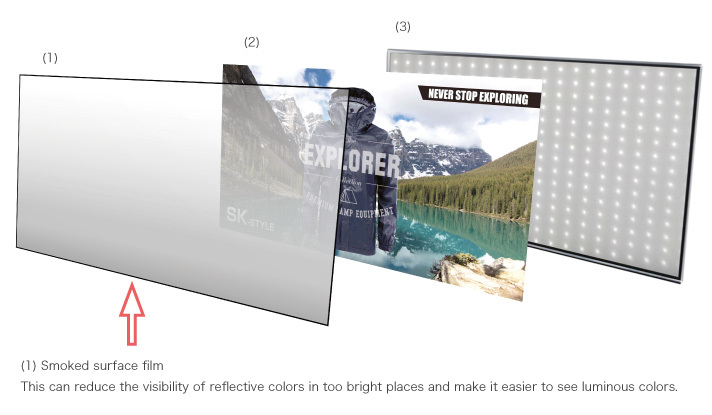

By using smoke film for adjustment

The spoiler can be improved.

If left as is

Concealing film processing

The smoke film is adjusted according to the color density of the original design and the brightness (lux) of the lighting device. This procedure eliminates the limitation of the design to be changed.The changing effect will be degraded under the sunlight or too bright environment.

How to deal with it

Image of smoked film on the surface

③About Triggers

Types of triggers to change the design of RELIGHT PRINT

| Trigger (1) |

| Just place it on the tracing table. |

| Trigger (2) |

| light control |

| Trigger (3) |

| Just let it shine in the sunlight. |